Quality

Baume & Mercier has been developing its expertise for 190 years. This expertise is based on the principle of manufacture, meaning every stage in the creation of a timepiece is controlled in-house, as is the assembly of its various components. This choice reflects the Maison’s strong principles and is a guarentee of the highest quality. This tradition of excellence at Baume & Mercier is based on the design and development of its products at the Maison's headquarters in Geneva, and on the manufacture process carried out at its manufacture in the Swiss Jura, in Les Brenets. This means that watch production is centralized in Switzerland. Baume & Mercier attracts the best talents to ensure it achieves the ultimate quality and respect for tradition; this has been the Maison’s strength since it was founded.

Design and development studio

Each of our watches is a result of the passion of our master watchmakers and a desire to innovate, which is reflected in thousands of sketches, hundreds of hours of modelling, and years of development.

The skill of our design studio lies in finding the balance between artistic creativity and technical possibilities, which is the responsibility of our development engineers.

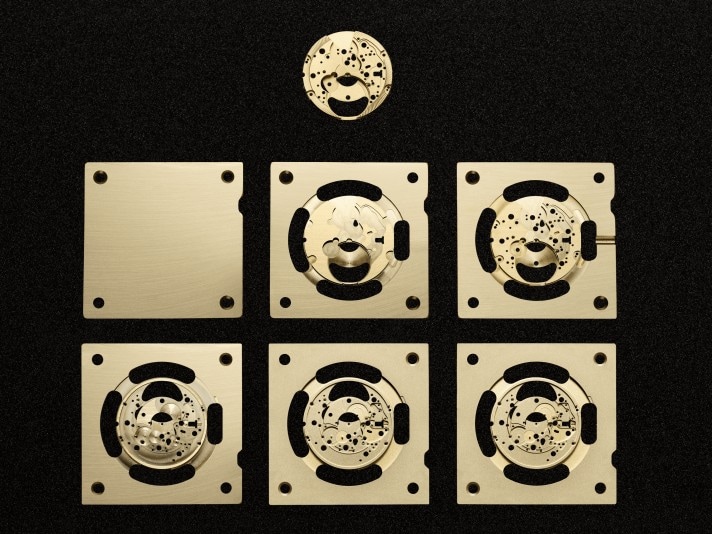

TESTING

The assembled calibers and cases are submitted to the most stringent individual tests to ensure every timepiece functions according to Baume & Mercier's specifications. The mechanical watches are tested on a machine for the movement’s accuracy and power reserve. Their function controls are also tested: setting the time, jumping date, chronograph and any other complication.

The watches then undergo thermal shock testing, which highlights any hidden flaws. Every watch made at the manufacture in Les Brenets also undergoes a number of visual and aesthetic checks. Lastly, to ensure consistent and flawless quality, each finished piece undergoes a final meticulous check before being sent to one of our approved retailers.